How to maintain a stretch wrapping machine for ongoing use

Maximize Lots Security With an Advanced Stretch Covering Machine for Safe Transport

In the realm of risk-free transportation, maximizing lots security preponderates. Advanced stretch wrapping devices offer an ingenious remedy, wrapping up tons with identify accuracy to stop shifting throughout transportation. With a suite of functions such as adjustable movie tension and automated capability, these devices provide constant vertical and straight security while reducing damages danger. Using leak and tear-resistant stretch movie, businesses can rest assured their products will get here intact. But how do these devices precisely improve tons security and effectiveness? Let's discover.

Recognizing the Role of Stretch Covering in Safe Transportation

While lots of may forget its importance, stretch covering plays a vital role in making certain the safe transportation of items. This procedure includes using a very stretchable plastic film that is twisted around items, generally on a pallet. The elastic recovery of the cover firmly safeguards the things with each other, protecting against movement throughout transportation.

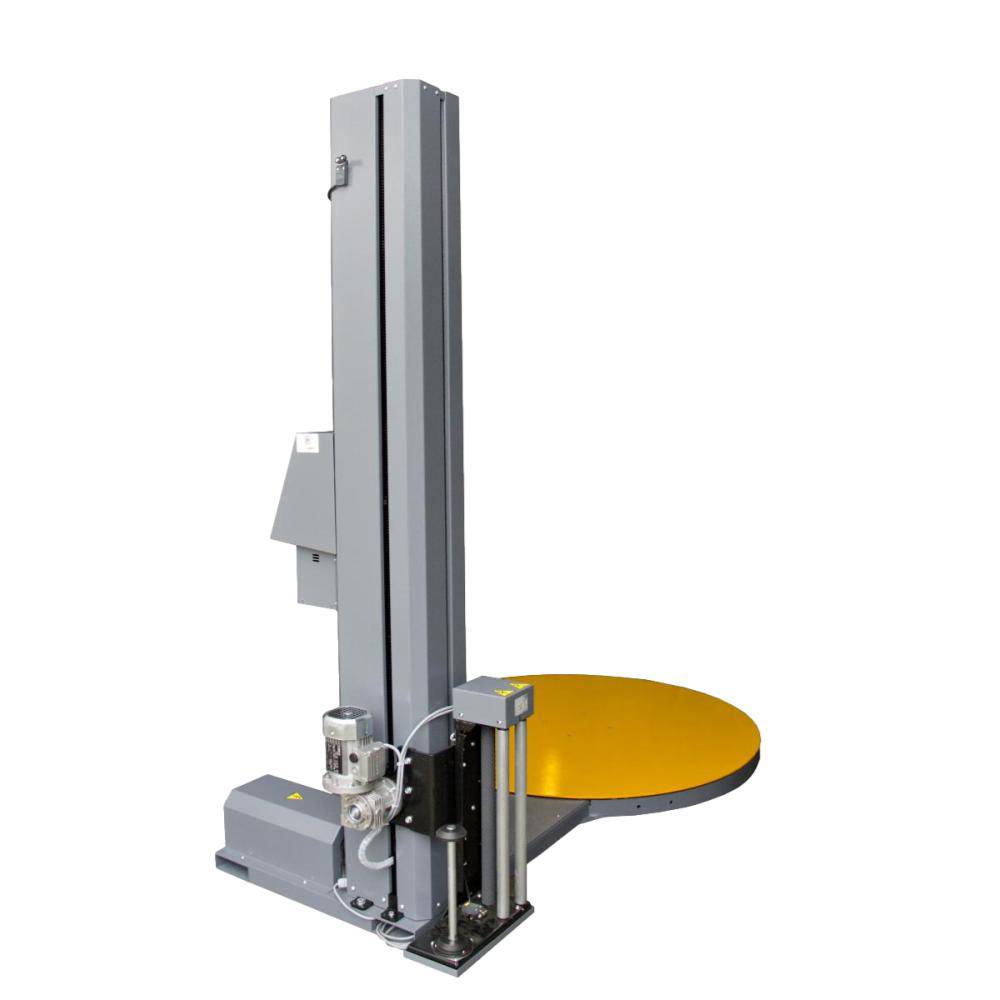

Secret Functions of Advanced Stretch Wrapping Machines

In the world of logistics and supply chain monitoring, advanced stretch covering makers have emerged as a game-changer. These makers are identified by several key features that differentiate them from their precursors. One of the most noteworthy attributes is their automated capability. They can cover tons without straight human intervention, reducing labor prices and raising efficiency.

Advanced stretch wrapping devices likewise include pre-stretch capabilities. This attribute enables the film to be elongated prior to being related to the load, optimizing movie usage and lowering expenses. In addition, these devices have adjustable controls for movie tension, allowing personalization based on tons size and form.

Ultimately, these machines are outfitted with incorporated load cells, which precisely measure the weight of the tons throughout the covering process. This function guarantees the equipment adjusts its operation based upon the weight, thus preventing damages and ensuring the load's risk-free transportation. Thus, progressed stretch covering makers provide a mix of automation, efficiency, safety and security, and cost-effectiveness.

Just How Stretch Covering Machines Enhance Lots Stability

Making certain that lots continue to be stable throughout transport is an important facet of logistics, and one that progressed stretch covering machines master attending to. These machines function by wrapping up the load in a protective film that holds all things securely together. This decreases the risk of products moving or falling during transport, thereby boosting lots security.

The machines utilize a sophisticated wrapping method that gives not only vertical however additionally straight stability. This dual-axis security better reinforces the tons and minimizes the likelihood of damage or loss. The consistent tension applied by the equipment throughout click for source the wrapping process makes sure that the load is portable and protected.

Potential Expense Savings With Effective Stretch Wrapping

Beyond boosting lots security, advanced stretch covering makers likewise use substantial potential for price financial savings. These equipments lower the need for manual work, hence lowering payroll expenditures. They additionally function quicker and more effectively than humans, causing increased efficiency.

The use of sophisticated equipments makes sure optimal usage of stretch film, which can lead to significant financial savings in product costs. Manual covering frequently leads to wastage as a result of inconsistent use movie. An equipment uses the best amount of film, getting rid of wastage.

Furthermore, the visit the site improved tons stability minimizes the danger of damage during transport. This can possibly conserve organizations from costly product losses and connected replacement prices.

Last but not least, the devices require very little upkeep, which converts right into lower repair and upkeep costs.

Selecting the Right Stretch Covering Device for Your Business Requirements

While the advantages of advanced stretch covering machines are apparent, choosing the appropriate one for your details service demands can be a daunting task. High-volume operations would benefit from automatic equipments with higher speeds, while semi-automatic equipments might be sufficient for smaller services. A thorough assessment of these variables can assist organizations towards the ideal stretch covering maker, therefore making sure safe transportation of their products.

Final thought

In verdict, advanced stretch wrapping makers are essential in making certain load security throughout transport. They use essential functions like adjustable movie stress and automation, offering both upright and straight safety and security. By minimizing the risk of damages, they can add to substantial expense financial savings. Businesses must consider investing in a suitable stretch wrapping machine, better boosting safety and security and effectiveness within their supply chain.

Advanced stretch covering devices provide a cutting-edge solution, enveloping lots with identify precision to avoid shifting during transportation.Making certain that loads remain steady during transportation is an important aspect of logistics, and one that progressed stretch wrapping equipments excel in attending to.Beyond boosting load stability, progressed stretch covering machines also provide significant capacity for cost savings. High-volume operations would certainly profit from automated devices with higher rates, while semi-automatic equipments might suffice for smaller companies.In conclusion, progressed stretch covering equipments are critical read the full info here in making certain load security throughout transport.